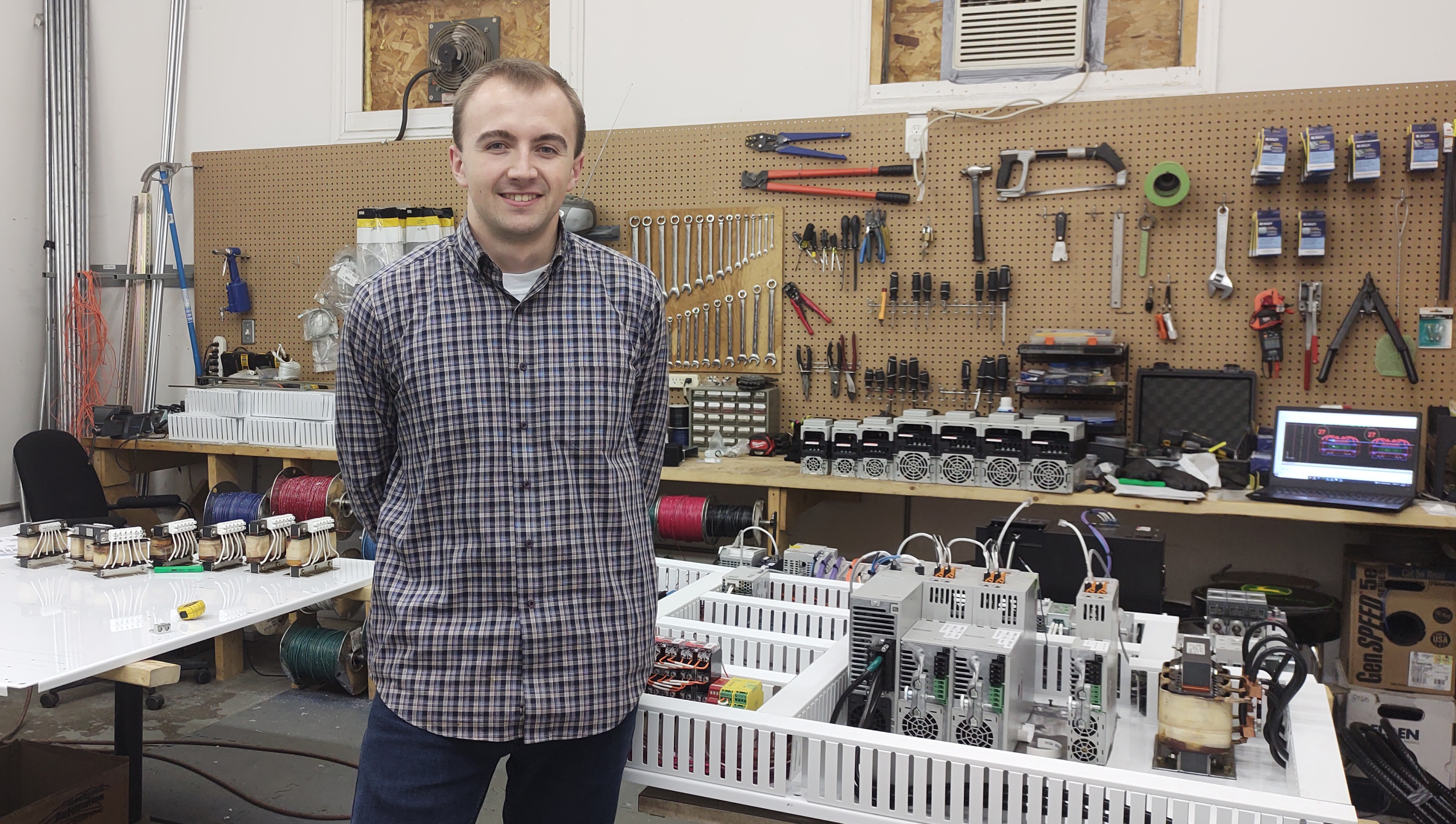

Todd Lavigne returns to NB as Production Manager at McDonough Canada

McDonough Canada recently welcomed Todd Lavingne as the new Production Manager in our Mactaquac, New Brunswick location. A native of New Brunswick, Todd brings with him extensive experience and knowledge in the manufacturing industry, and is happy to be back home after 26 years in Ontario.

-1.jpg)