Our Products

Engineered Sawmill Equipment for Modern Mills

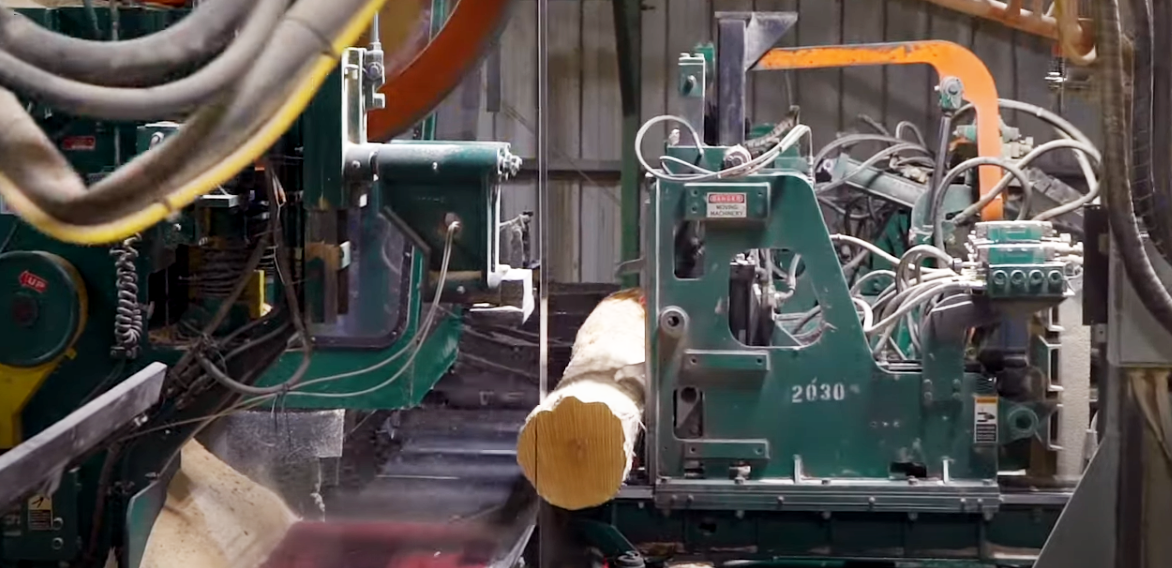

For over a century, McDonough Manufacturing has been a trusted name in the sawmill industry, delivering innovative, heavy-duty equipment that stands the test of time. Whether you're looking to upgrade a single piece of machinery or outfit an entire mill, we offer custom-built solutions tailored to your exact needs.

From bandmills and edgers to resaws, carriages, and complete material handling systems, our equipment is engineered to maximize uptime, improve board quality, and increase throughput, because downtime isn’t an option.

Edgers

Our board edger lineup spans high-speed optimized systems to rugged manual units

- OptiFit Linear Edger: Designed for hardwood mills, delivers maximum yield with minimal footprint; maintains board counts up to 40 pieces/minute with a short-coupled outfeed system

- Optimized Transverse Edger: Versatile design handles both boards and cants in the same machine, driving efficiency and payback speed

- Sterling YieldBoss Hybrid Edger: Combines optimized saw placement with manual edger simplicity—built for mid-range mills seeking top yields at competitive pricing (starting around $517,000)

- Manual & Combination Edgers: Durable 2‑saw/3‑saw systems, and combo board/gang models for simpler mill setups

Resaws

McDonough’s resaws and headrigs are industry benchmarks. We offer a full lineup:

- AutoMAXX Resaw (vertical and horizontal): High-output systems tailored for hardwood mills

- MAXX Infeed Resaw: McDonough’s fastest linebar feed system—eliminates air cutting and boosts efficiency

- Modular Horizontal Resaw: Budget-friendly option delivering 200 FPM+ feed rates—ideal for slab, cant, or multi-board cutting

- A-Series Horizontal: Heavy-duty flagship horizontal resaw for high-production slab recovery and cant operations

- Linebar Resaw: Iconic McDonough design dating to the 1890s, enhances production, grade, and yield

- Sterling 44″ Horizontal: Affordable, durable horizontal resaw compatible with thin-kerf blades

- 54″ Center Split: Historic model, in production since 1888—timeless engineering

Bandmills

Premium double-column air-strain bandmills from 54″ to 96″ throat widths set the industry standard. Built on heavy-duty, plate-steel frames with independent columns and bases, these mills feature:

-

Exclusive Air-Strain system to maximize feed speeds and reduce mis-cuts

-

Cartridge-type pressure guides that improve accuracy and simplify maintenance, including a Guide Block Dressing Machine

-

Cast-iron wheels for blade tension consistency and reduced heat

-

Hydraulic top guide and wheel lift, Timken railroad-car bearings, automatic saw cleaning and lubrication

Gangs

McDonough gang edgers are built for power, precision, and yield. Available in conventional, shifting arbor, cluster, and combination board/gang configurations, they’re designed to process cants quickly and accurately with minimal waste. Features include:

-

Heavy-duty steel frames

-

Shifting saw and fixed arbor options

-

Advanced setworks for optimized cutting

-

Compact designs for mills with limited space

-

Easy maintenance access and durable construction

Whether you’re maximizing recovery or handling mixed hardwoods, McDonough has a gang edger to fit your line.

Carriages

McDonough carriages are built for precision log breakdown with modern mill demands in mind. Features include:

-

Available openings: 36″, 42″, 48″

-

UHMW cant kickers, 17° slanted beds, round-way knees

-

Options for Brownsville or chain turners, Tong Dog rail systems, and hydraulic drives

-

Integrated computerized setworks for repeatable cuts

-

Full operator cab packages available

Designed to improve both cut quality and throughput in high-production headrig applications.

Material Handling

Our material handling systems ensure smooth flow from log infeed to finished lumber. Options include:

-

Lumber transfer decks

-

Chain decks, rollcases, and log decks

-

MAXX Resaw Infeed – our highest-speed linebar feed system

-

Modular or custom-engineered systems for new installations or retrofit integration

-

Designed to integrate seamlessly with McDonough machinery or equipment from other OEMs

These systems are engineered to reduce manual movement, improve mill flow, and increase throughput.

Have Questions?

Reach out to Bob Bell at bbell@mcdonoughmfg.com to learn more.