Tom Schwahn Appointed as Customer Service Manager at McDonough Manufacturing

McDonough Manufacturing is pleased to announce the appointment ofTom Schwahn as Customer Service Manager, effective immediately.

Posts about:

McDonough Manufacturing is pleased to announce the appointment ofTom Schwahn as Customer Service Manager, effective immediately.

McDonough Manufacturing is proud to announce the appointment of Bob Bell as Director of Sales and Service, effective May 19, 2025.

Before we get into the exciting work we’ve been doing with Gates Milling, we want to take a step back and talk about the people behind the name—and why we’re so proud to be partnering with them.

Troy Whitman is a seasoned sales professional with over 20 years of experience in building relationships, solving challenges, and driving results. As a key part of the BID Canada team, Troy works closely with clients to deliver tailored solutions in the material handling industry. From belt conveyors to screws and bucket elevators, Troy’s expertise ensures that customers get the right products and support to keep their operations running smoothly.

Troy’s success stems from his ability to spot opportunities and stay ahead of industry trends. Certified by the Canadian Professional Sales Association (CPSA) and having completed Northwestern Kellogg’s Mastering Sales program, he brings a unique mix of formal training and hands-on experience to every project. He’s passionate about finding practical, effective solutions while keeping things straightforward and results-focused.

At BID Canada, Troy is all about collaboration. Whether it’s working with customers to solve specific challenges or supporting his team to meet their goals, he knows that success comes from working together. His approachable style and commitment to building strong relationships make him a trusted partner in every interaction.

When he’s not on the job, Troy keeps busy coaching hockey, where he instills values of teamwork and discipline in young athletes. He’s also an avid traveler and outdoors enthusiast who’s always up for a new adventure. Whether at work or play, Troy brings the same energy, curiosity, and problem-solving mindset to everything he does, making him a valuable part of the BID Canada and McDonough family.

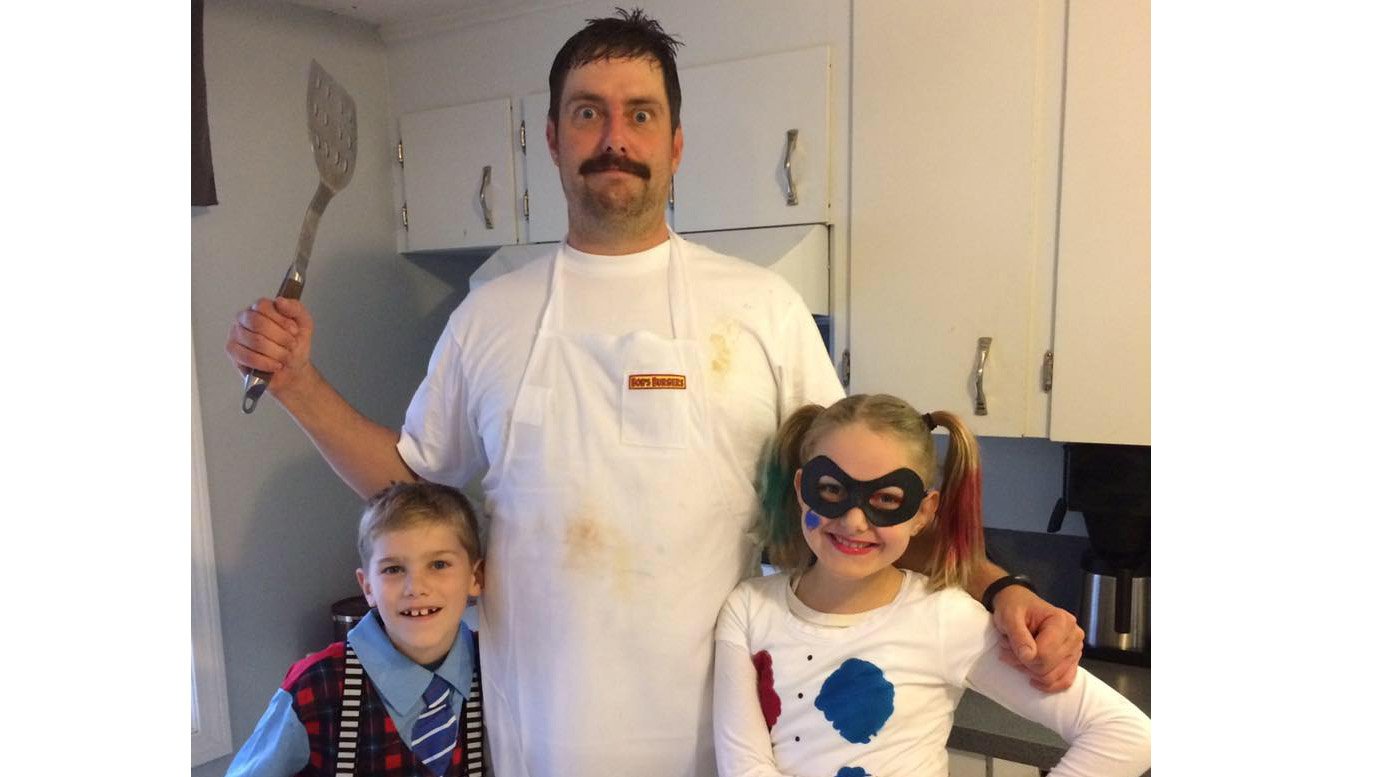

The personality that keeps the Mactaquac shop on its toes, Chad Connors is equal parts engineer and entertainer. He’s the guy most likely to show up to work with a new moustache, his Mr. Rogers or Elton John t-shirt, or purchase a salt-firing air gun to terminate houseflies. He’s also an integral part of the work we do and getting it into the customers’ mill.

McDonough is pleased to have welcomed Travis Shepherd to the team in the role of Senior Technical Sales & Support.

It doesn’t take long when speaking with anyone at Elmsdale Lumber Company (ELCO) or browsing their website to learn that one of the foundational principles at ELCO is their commitment to the lifelong learning of their employees. McDonough is fortunate enough to have kickstarted various projects with ELCO recently, and through our conversations over the last number of months, we began to hear about something called ‘Mel’s Story’.

Ryan Hemauer is a machinist in our Eau Claire shop, who brought a wealth of experience, education and a strong work ethic along with him. Learn more about his work experience and advice to future machinists in our one-on-one interview.

The driving force behind McDonough is our team – the folks in the shop and offices every day who have made it possible to produce high-quality machinery for over 130 years. Right alongside us throughout our success are the industry partners who help with our equipment installations and service calls all over the continent and world. Chief among these valued colleagues is Ray Tharpe of RTM Industrial Maintenance (RTM), who we have worked with in one capacity or another for almost 20 years.

In a previous blog, we outlined the components of a linear edger system and their intended purpose. Now, we’ll take a look at the alignment and calibration of your linear edger.

To refresh, a linear edger operates under the basic principle that we can scan a piece of lumber while it is in one location and then ‘edge’ it when it reaches another, without handling it in between, by accurately predicting where it is going to be throughout the process.