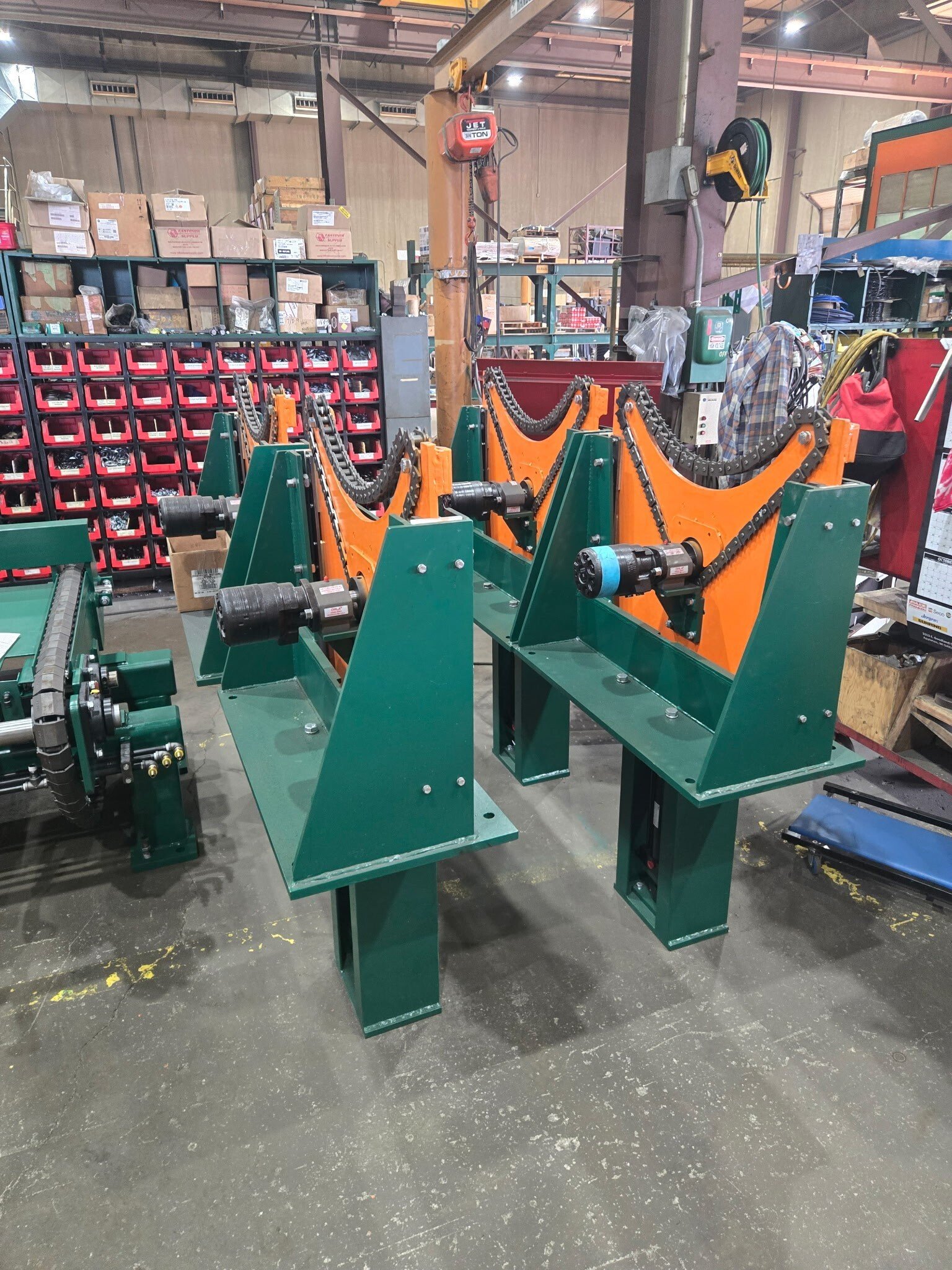

Progress in Motion: Jones Lumber 6’ Resaw System Coming Together

We’re making good progress on the custom-built 6’ Resaw system for Jones Lumber, and things are starting to come together. The system features a Maxx infeed, full run around setup, cant turners, roll cases, and a 3 press roll capable of processing cants up to 24” x 24”. It’s a big step toward improving flow and efficiency for our valued partner.

This project follows the successful installation of a McDonough OptiFit Edger in the summer of 2023. Building on that momentum, Jones Lumber is now upgrading from their older horizontal resaw to a McDonough Linebar Resaw, engineered for excellent accuracy, higher feed speeds, and improved recovery. It’s a solution tailored to their evolving production needs, offering long-term value and consistent performance.

The Maxx infeed included in this system is outfitted with a laser cant measuring device that scans the height and width of each cant, ensuring precise positioning for optimal recovery. High-speed angled speed-up chains and stop hooks ensure that cants are fed butt-to-butt for smooth and efficient throughput. The entire infeed and outfeed system runs on VFDs (variable frequency drives), allowing for seamless transitions through every stage of the process. This automation lets the operator stay focused on grade and quality while the system handles the high-speed flow of production.

This exact 6’ Resaw system will be on display at the Forest Products Machinery & Equipment Expo in Nashville. If you're attending, swing by the McDonough booth to see it in person. We’ll be there to talk about the build, walk you through the system, and answer any questions you’ve got about optimizing your own sawmill operations.

Stop in and say hello, we’re looking forward to it!

-1.jpg)