Building for Growth: A 6 Foot Quad Band Mill for Two Rivers Lumber

Work continues in the Eau Claire shop on a 6 foot Quad Band Mill being built for Two Rivers Lumber Company, a Southern Yellow Pine producer that is in the midst of a significant mill expansion in Alabama.

Two Rivers Lumber has announced plans for a large scale sawmill project in Coosa County, representing a major investment in new capacity and long term growth. The expansion is expected to create more than 130 jobs while strengthening regional timber markets. As operations grow, equipment decisions become increasingly important, with a focus on reliability, consistency, and the ability to support high volume production over time.

Built to Support Modern Southern Pine Operations

The 6 foot Quad Band Mill currently being finished in Eau Claire is designed with those needs in mind. At its core, the machine is built for stability, accuracy, and dependable performance in demanding sawmill environments.

Key features of the mill include:

-

A 6 foot cutting capacity to accommodate larger diameter logs commonly found in Southern Yellow Pine operations

-

12 inch wide by 40 foot long sawblades that provide stability through the cut and support consistent lumber sizing

-

Precision round way shifting for both saw sets and saw changes, allowing accurate positioning and long wear life

Band wheels capable of running surface speeds of over 13,000 SFPM, supporting efficient cutting while maintaining control

Together, these features support steady throughput while maintaining the dimensional accuracy required in competitive lumber markets.

What a Quad Bandmill Does and Why It Matters

A quad bandmill typically:

-

Uses four band saws arranged to cut multiple faces of the log in a single pass

-

Applies cutting forces more evenly around the log

-

Reduces the amount of log movement or rotation during breakdown

Because the log is being acted on from multiple sides, cutting forces are more balanced than with a single or twin band system. This balanced and controlled approach is especially valuable in high volume operations processing a wide range of log sizes.

How Balanced Cutting Supports Consistency

Balanced cutting plays an important role in overall mill performance because:

-

Less log deflection during the cut helps maintain straight faces

-

Reduced vibration supports more uniform board thickness

Consistent positioning helps maintain dimensional accuracy across log sizes

In Southern Yellow Pine operations, where log diameter and taper can vary significantly, this balance helps mills maintain consistent lumber sizing without constant adjustment. Over time, that consistency supports improved recovery, even if gains are incremental rather than dramatic.

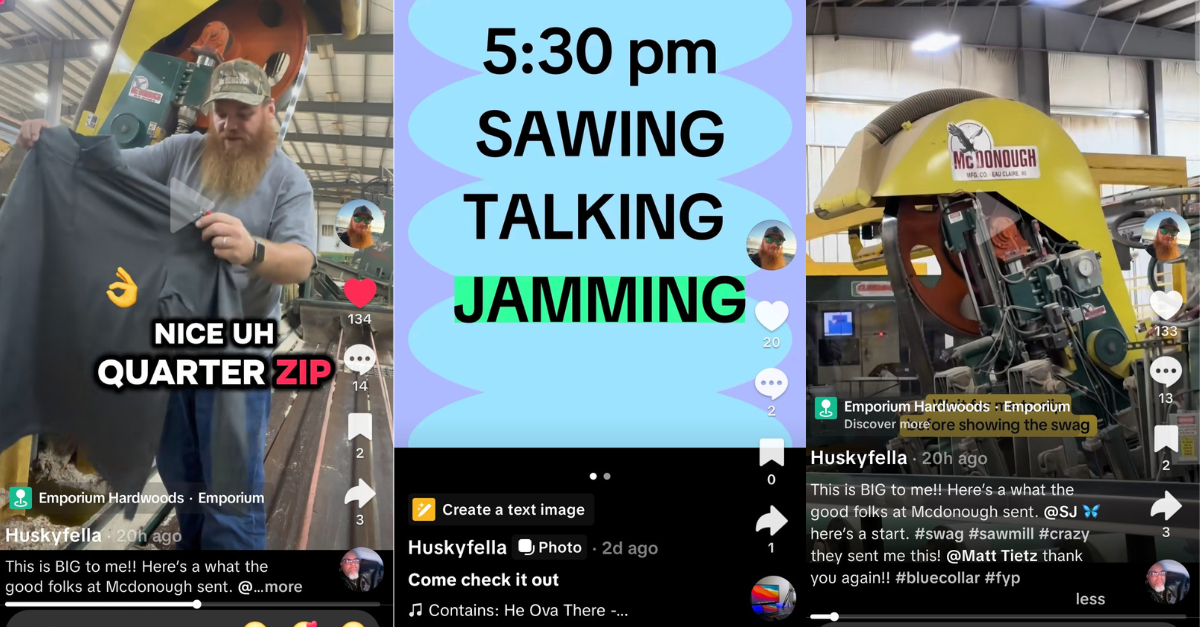

Final Stages in the Eau Claire Shop

Final assembly and finishing work on the 6 foot Quad Band Mill are ongoing in the Eau Claire facility, with close attention paid to alignment, fit, and testing. Once complete, the mill will be prepared for shipment and installation as part of Two Rivers Lumber’s expanding operation.

Projects like this highlight how growing sawmills continue to invest in proven band technology to pair increased capacity with dependable performance, supporting both current production needs and long term operational goals.